Horizontal and Double End Machines

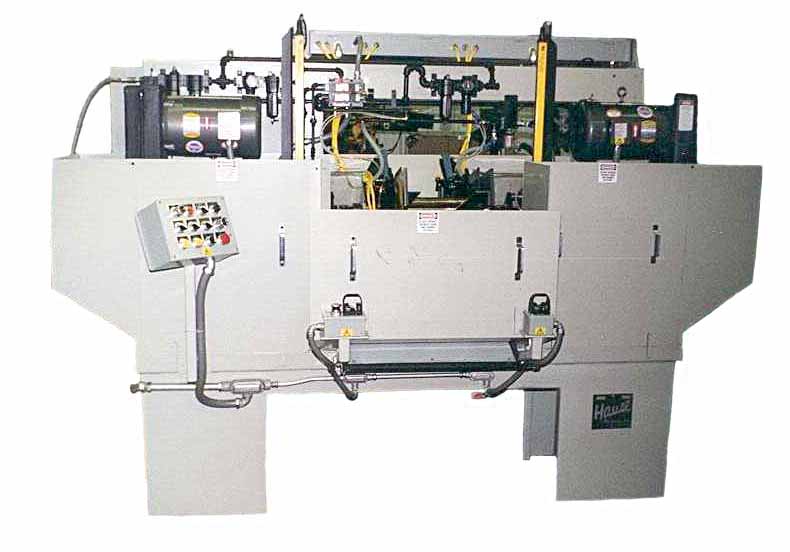

Hause has designed and built hundreds of double end machines. We often start with our “Basic Single End or Double end, an untooled version with no fixture, and modify to suite. We also offer fully custom double end machines. Needing to prep shafts for a lathe? Pipe nipples, tubing, or face and center? Door hinges, rod ends, and counter bore drive yokes are all manufactured using these machines. Start with a “basic” untooled machine and add you own fixture or have Hause design one just for your product.

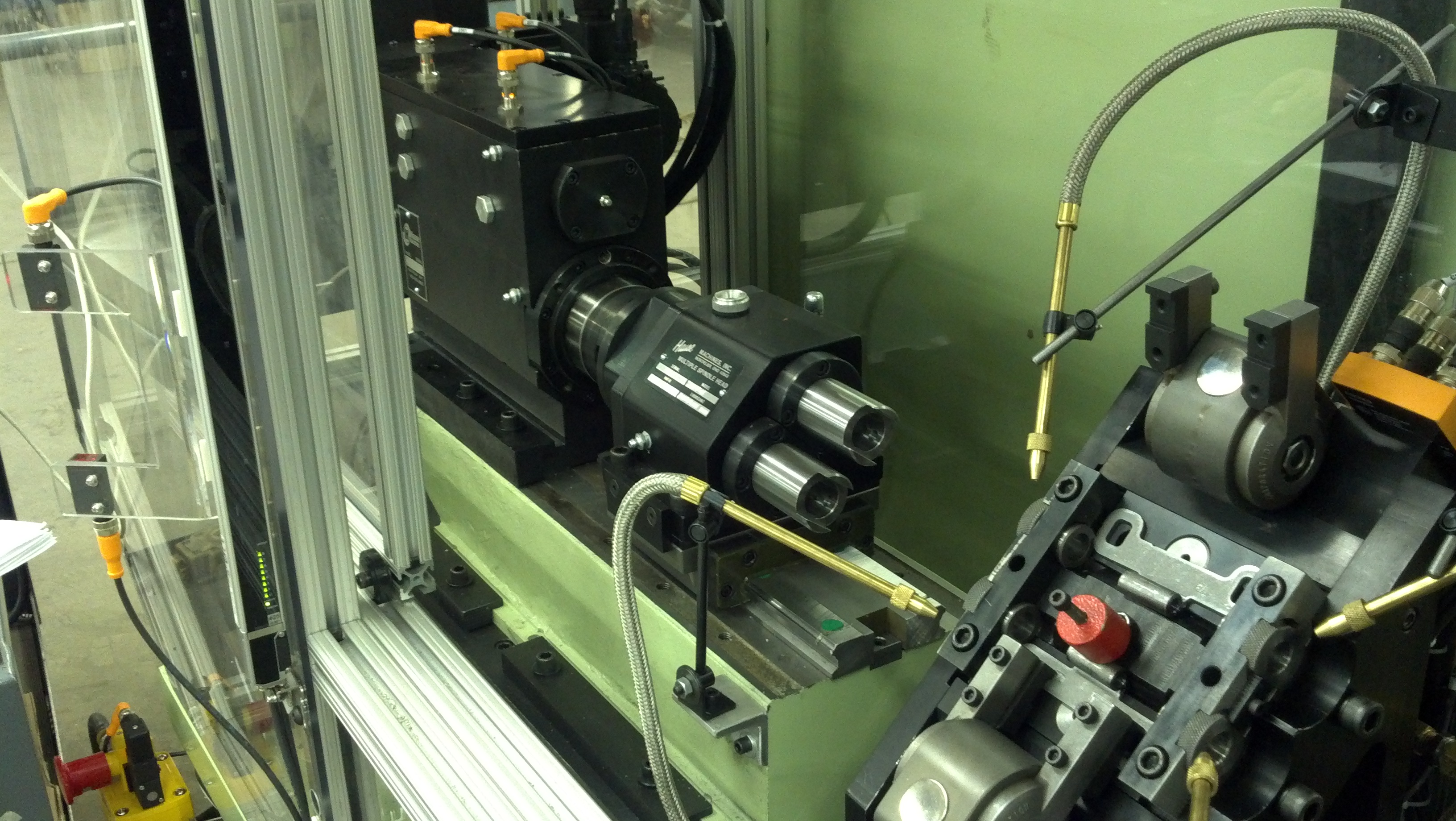

The machining unit could be servo, dual servo, hydraulic, air, or leadscrew for tapping or die head threading.

Everything you need to build your own. Two machining units a 13 x 72″ base, a coolant system, hydraulic system (optional), and control package with basic manual and automatic controls of the unit and fixture. Add your fixture and tools and your ready to go.

13 x 48″ or 13″ x 72″ fixture mounting area, 3/8″ pneumatic FRL and (2) valves, 20 gallon coolant system, Allen Bradley Micrologix PLC, 6″ HMI.

Basic Horizontals

004-005 Autocad

004-005 Solidworks

004-005 Stp

Choose your unit from our Quill style units page.

Add servo control, VPN remote router, hydraulic system, automation, shielding.

Or Contact Hause to specify what you need.

We’ve solved this many times. Double ended threading machines for making pipe nipples, sprayer tubes, shock absorber shafts, etc. Double end ID / OD and face machines for tubes

SPEC

Pneumatic, hydraulic, lead screw, or servo units available.

From 1″ bearing blanks to 120″ pipe

up to 15 HP AC Spindle motors, or dual axis Servo

Allen Bradley PLC and HMI

Brass plumbing parts, oil and gas nipples, or automotive air conditioning condesor housings.

With or without a coolant system

For more info, Contact Hause Machines

Face and center a forging or a saw cut bar to prep it for a lathe. Or center, face and OD chamfer. For other custom machine needs, contact Hause Machines

SPEC

24″ ballscrew slide for length adjustment

Custom Fixturing based on part specifications.

up to 15 HP AC Spindle motor.

Allen Bradley PLC and HMI

Face and center drive yokes, transmission shafts, or other Automotive components.

80 gallon coolant system with magnetic conveyor.

For more info, Contact Hause Machines

Larger 24″ slides and boring spindles on each end. This machine was used for engine heads. A similar machine drills out bull-dozer track for coal mining equipment. Many other parts could use this type of arrangement. For other custom machine needs, contact Hause Machines

SPEC

24″ ballscrew slides with 6″ block spindles

Custom Fixturing based on part specifications.

up to 15 HP AC Spindle motor.

Allen Bradley PLC and HMI

Coal mining equipment, automotive parts, Heavy equipment, or other components.

200 gallon coolant system with magnetic conveyor and filter system.

High pressure thru the spindle coolant.

For more info, Contact Hause Machines

809 S. Pleasant St. Montpelier, OH 43543

Call us

419.485.3158

Contact us

sales@dialmachines.com