Custom Machines and Machine Systems

Engineered Solutions for Manufacturing Excellence.

We help production engineers and manufacturers maintain manufacturing excellence by providing custom machining systems

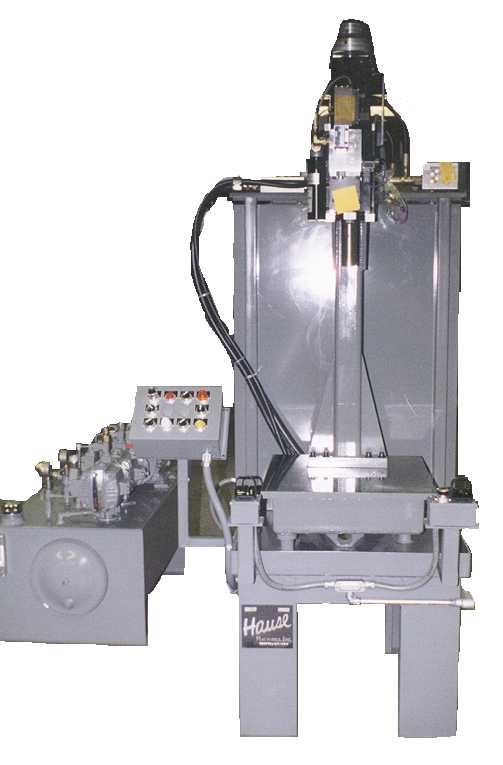

Vertical machines are in essence really well built, automatic drill presses. Typically a single operation or the basis for building your own machine. The unit could be a drill, reamer, tapping, servo, or could be fitted with a multiple spindle head. Fixtured or not,

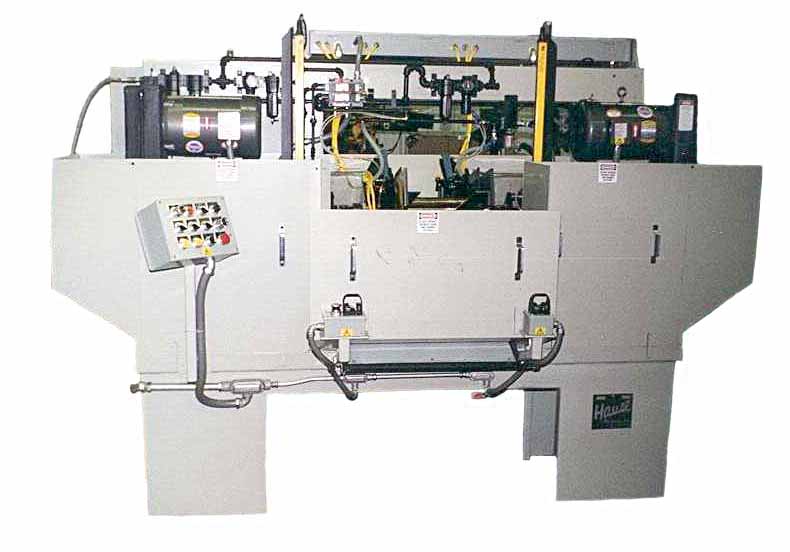

Double end machines are great for working both ends of a shaft, pipe nipples, door hinges, etc. Fully tooled with chute feed, or a “basic” machine to build your own. We have several pre-designed systems or we can work with you the have a complete custom machine built for your process.

They are like multiple double end machines in one. Large trunnions are like the smaller ones with more machining spindles. They are great for machining multiple operations on both ends of a shaft, turn buckles, drive Yokes, etc. Some of these include milling stations, along with the end working stations. Fully tooled with chute feed, robotic load, integrated with a bowl feeder or operator load.

Gantry machines use multiple machining stations but use an over-head arm to move the parts along through the machine. the arm can often pick parts from a conveyor, move them through the machine, and place them back on an exit conveyor. They allow machining from front and back of the part. Brake Rotor drilling / reaming are a good example of gantry machines with multiple spindle heads incorporated.

Dial machines use multiple machining stations for high volume machining of a part. Machining operations can be vertical (on columns), horizontal (on risers) or at almost any angle required to complete the part. We incorporate multiple spindle heads, 3-axis units, slides, spindles, and / or other special machining components.

When more than just a machine is required, we can help you integrate feeder systems, robotic load, parts washers, conveyors, and most other upstream or down stream systems. When it all has to work together, we can help make it all work together before it gets to your floor.

When something truly unique is required, challenge us. We can help develop something truly special. Maybe a portable machine that sits in an engine shipping cradle to drill a 2″ clearance hole, or an extra large horizontal mill for making snow plow blades, or even a large spot spot face machine for cleaning up welded tubes inside a 36″ diameter tube for heat exchangers. Yep, we’ve built them all.

809 S. Pleasant St. Montpelier, OH 43543

Call us

419.485.3158

Contact us

sales@dialmachines.com