MACHINING COMPONENTS

BY HAUSE MACHINES

Hause has many of the tools required to fulfill your specific requirements, already designed. Our standard self feed heads, slides, and spindles can be used for a variety of application. Pre-designed (i.e. lower cost, quicker delivery), yet high quality and backed by our guarantee and warranty. As the major supplier of machine building components, Hause has developed a number of ready-to-go machining modules. These components are available with limited number of choices (motor size, rpm, spindle nose.) If one of these do not fit the bill for your application, We specialize in designing a module that will work for your application.

Drill, Ream, Counterbore, Tap. These units are used for all types of end work type machining like drilling holes and finishing them, in steel, aluminum, stainless, cast iron, brass, etc. The link below will direct you to the quill units page for further information including specs, catalog pages, and CAD data.

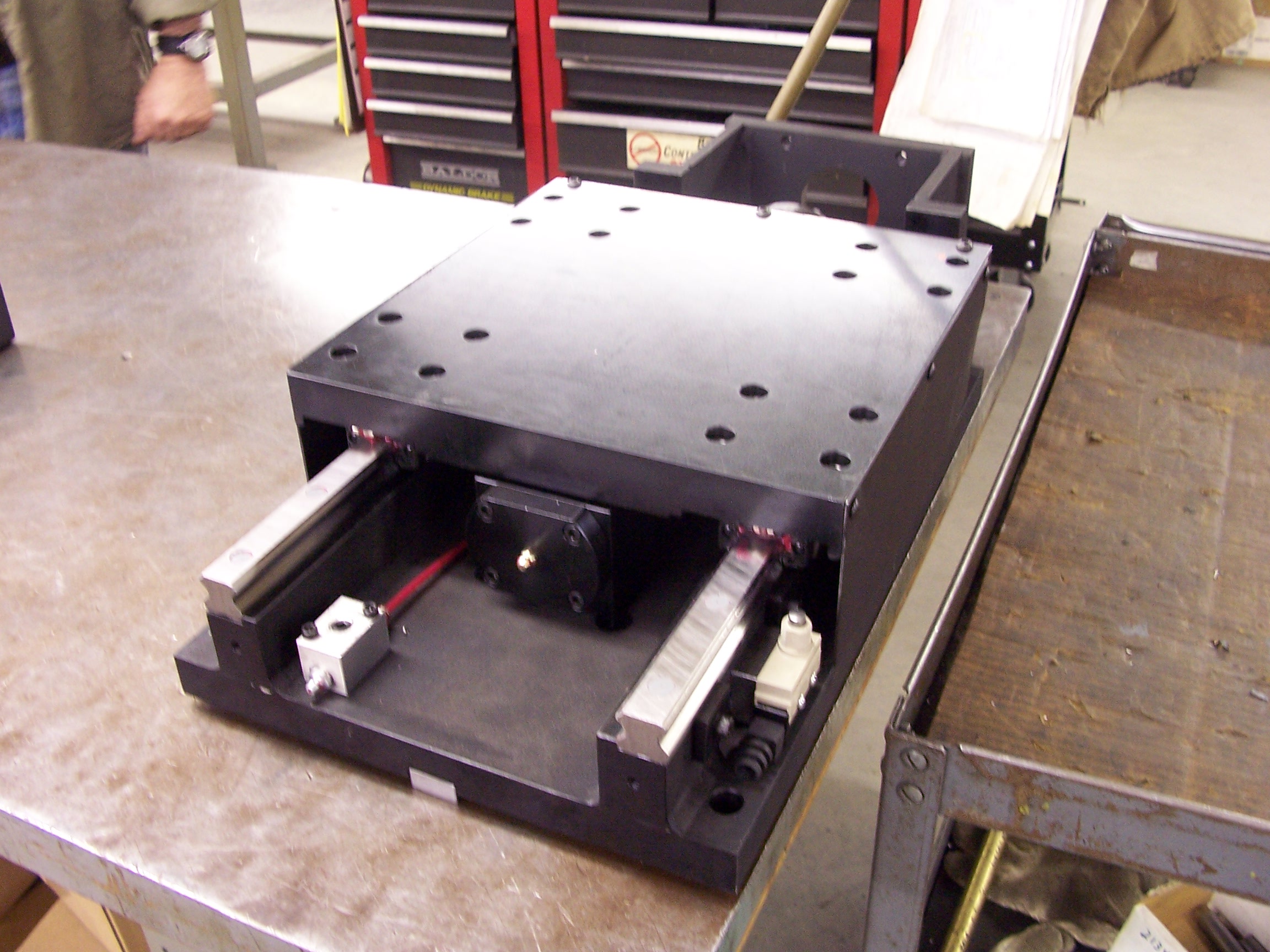

Move fixtures or move machining units. These slides are used to move things around. They can be ball screw driven for programmability, or hydraulic with a feed valve. The link below will direct you to the slides page for further information including specs, catalog pages, and CAD data.

Either turning the part or turning the tool, these heavy duty spindles get things turning. There’s a list of standard machining spindles, and many custom designed spindles with integrations like MQL, tool changers, and coolant through the spindle. Paired together with a slide, it makes a great machining module. The link below will direct you to the spindles page for further information including specs, catalog pages, and CAD data.

Patterns. Multiple spindle heads, mounted to the front of a Quill unit, a slide with a motor, or retro fitting an old NATCO drill press, these custom designed or off-the shelf adjustable heads are great for putting multiple holes into a part at once. The link below will direct you to the multiple spindle head page for further information including specs, catalog pages, and CAD data.

Solid machine bases, standard columns, custom risers, stress relieved and machined to your requirements. Black oxide, paint, or just primer? Fabricated and machined to your print or have an engineer design just what you need.

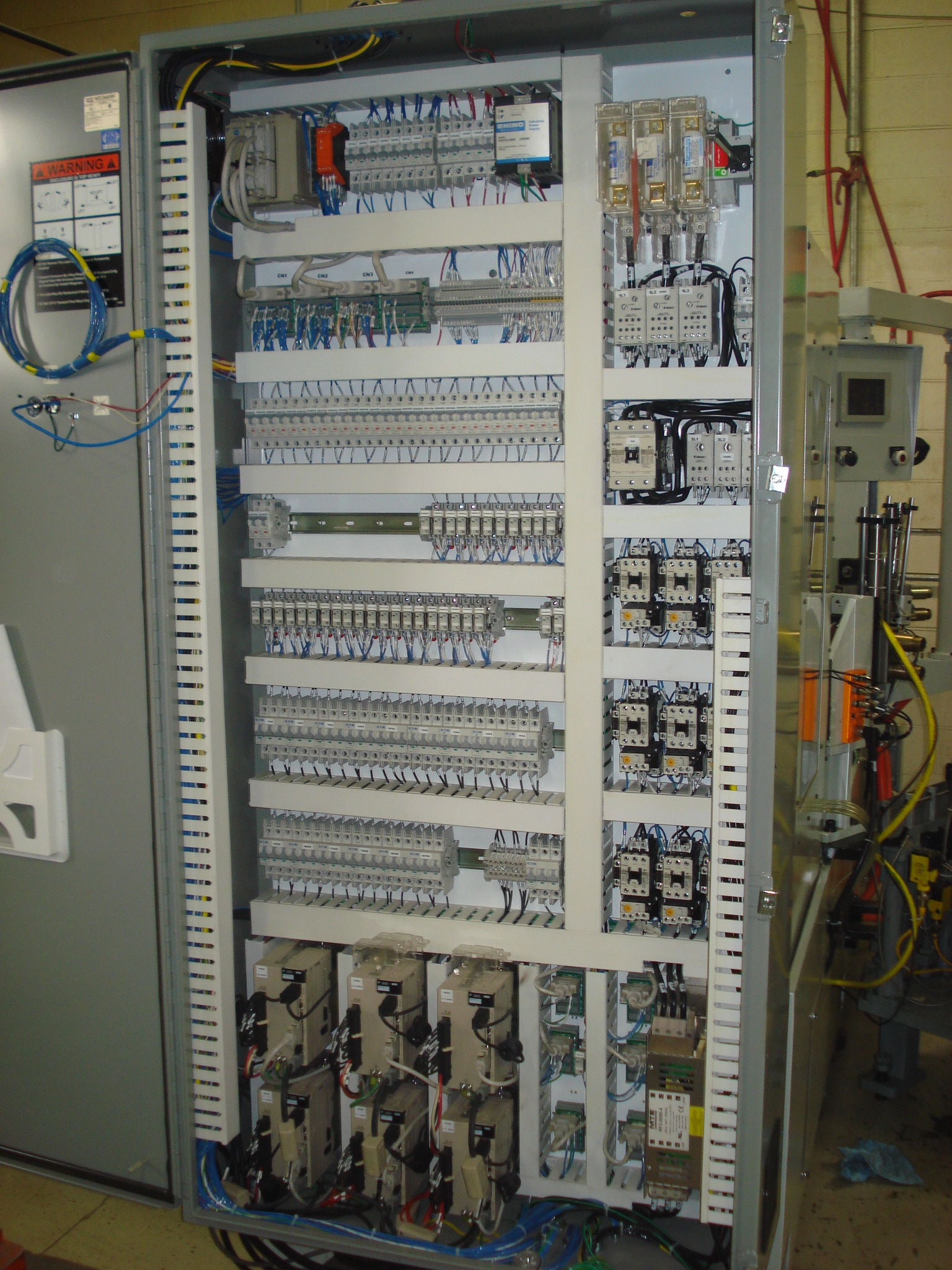

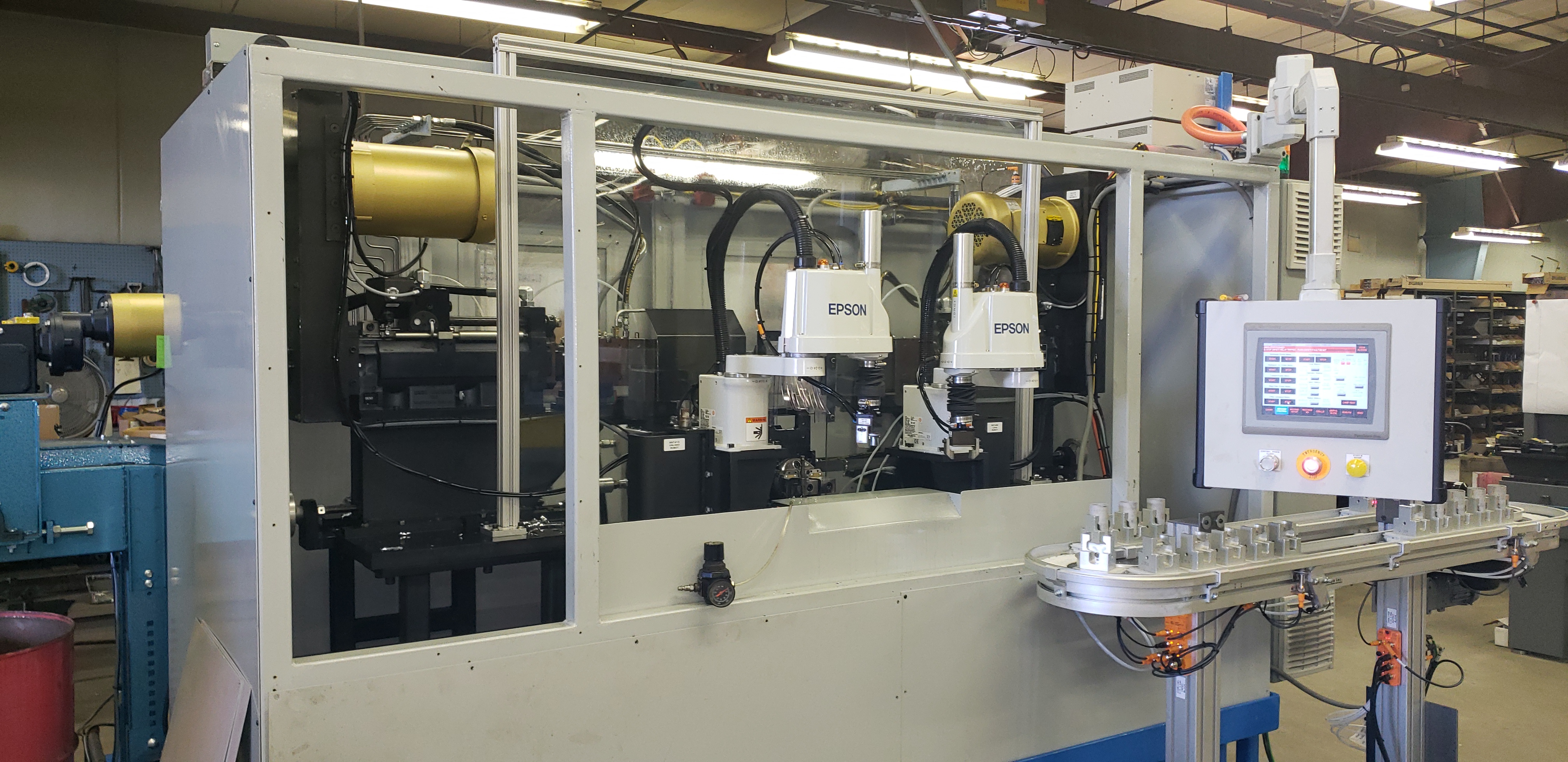

OK, Maybe you want the whole thing. Our engineers design and build entire machines, cells, or systems integrating everything from robots, washers, conveyors, and feeder systems. The link below will take you to the machine systems page where we discuss the various styles of machines.

809 S. Pleasant St. Montpelier, OH 43543

Call us

419.485.3158

Contact us

sales@dialmachines.com